Collaborates with KOTRA Chennai to identify Specialty Flexible Flat Cables for the Indian market.

By Industry Editor Joy Cho with Reporter Stephen Kim

International Flat Cable (IFC) is a leading world-class supplier which has specialized in the manufacture of Flexible Flat Cable (FFC) lamination equipment for more than two decades, using accumulated knowledge and extensive experience.

IFC has been manufacturing and exporting FFC laminating machines and post-processing equipment that produces flexible flat cable (FFC) for about 26 years. IFC has spread the advanced technology to the world. This was disclosed by CEO Joo Seong-Cheol of IFC.

Then he said, “Since its foundation, plenty of companies, including Sumitomo, Hitachi, Sony, Tsujimoto in Japan, Nicomatic, Parlex (Johnson Electric) in the United States, Foxconn, Tennrich, SHS, Deren in China, and TungHing in Hong Kong, have imported IFC’s products.”

Before the foundation, according to Joo, IFC already had an experience in exporting military flat cables to ESC, a US military supply company and supplying PTFE flat ribbon cables for guided missiles from the Defense Research Institute.

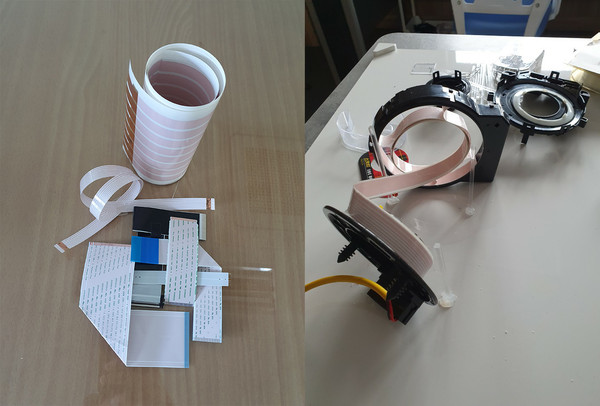

The card cable making machine, which had been heavily dependent on Japanese imports, according to Joo, Now the technology has been finally localized and the company expects 10 billion won of profit. Joo Seong-Cheol, the owner and the founder of International Flat Cable, succeeded in the production of the reverse cable laminating machine that can make card cables and started supplying them to domestic market as well as abroad.

International Flat Cable announced that it plans to introduce new products using laser cutting technology in the second half of this next year. They plan to export to the US, Japan and Europe and it will be sold domestically as well.

“IFC not only manufactures polyester (PET), which is the insulation material of existing FFC, but also manufactures flat cable production machines using high-end insulation materials such as PTFE and POLYIMIDE, as well as the manufacturing technology of the cable. We are IFC is the leader in the field of flat cables. As flat cables, which previously were primarily used in products such as electric, electronic, and communication devices, become increasingly utilized in applications such as health and medical care devices, robots, automotive airbags and electronics, and batteries of electric vehicles, the demand for flat cables is skyrocketing.

“In particular, the automobile airbag cable (clock spring) manufacturing machine has a 100% market share in Korea. In line with the recent diversification of flat cable applications, the recently developed flat ribbon cable has a flat conductor and a round conductor arranged together to reduce cable manufacturing costs by more than 20%.”

Excerpts from the interview follow:

Question: Please elaborate on your business in India.

Answer: There are lots of global automobile companies and home appliance manufacturers that are already in India because of their large territory and abundant labor force. Although India is desperately looking for Flexible Flat Cable (FFC), which is crucial for producing advanced technologies, most of their products are imported from Korea, Japan and China, due to the lack of FFC industries.

Prime Minister Modi’s Ministry seemed to be interested in producing FFCs by themselves, they have been attempting to support the Indian market introduction, as they realized the importance of FFC market.

IFC has been supporting them by sharing information about products, discussing marketing strategies and localizing the products. The first order from India for a FFC machine from IFC was placed in December 2019 and will be installed and personnel trained in March of 2020. We will continue to cooperate further to develop India as a competitive market for FFC industries.

In India, leading global automakers and global consumer electronics manufacturers are strategically positioned to utilize low cost abundant labor, large consumer markets and reducing costs normally caused by high tariff import barriers. Flexible Flat Cable (FFC) is a key element for producing these cutting-edge products at competitive prices.

Demand is exploding ! Manufacturing at lower costs, locally produced FFC cables are critical. Local production of FFC cables has now begun thanks to the help of the world leader, IFC. This eliminates the dependency and higher cost associated with having to import from Japan, Korea and China, etc.

Local cable importers are interested in direct production in accordance with the Indian government's “Make in INDIA” policy. International Flat Cable (IFC) has been aware of its potential for years and is committed to entering the Indian market. They have shared their FFC product information, produced various samples, and supported various products through KOTRA Chennai business, focusing on exhibitions in India through cable market research, buyer discovery, and meeting with cable importers. We signed the first machine export contract in December 2019, emphasizing win-win cooperation in India's local production, including consultation of the country’s sales strategy. The starting point is the production of cables suitable for increasingly precise and miniaturized electronic devices such as airbags, automotive electronics, electric vehicle batteries, and smart home appliances.

IFC has developed equipment and automated post-processing machines to continue consultations with local cable suppliers. IFC is working closely with local companies to help them succeed.

Q: What is your impression of the economic relationship between Korea and India? How do you think you can strengthen the relationship?

A: I used to think India was a country of infinite potential with large land and an abundant labor force. In reality, except for some major industries such as satellite and defense science, they lack of infrastructures such as roads and harbors which is critical and relied on for imports.

Lately, Prime Minister Modi launched the ‘Make in India’ campaign to facilitate investment, foster innovation, enhance skill development, protect intellectual property & build best in class manufacturing infrastructure. I’m sure this will make a big economic difference and Korean companies seemed to be interested in expanding their sales to the India market. If Korea cooperates with India with its advanced technologies, it will be a great Partnership. From what I have noticed, Indians seemed to have a strong pride about themselves, they are genuine.

I think it’s perfectly fine for them to have a pride about their cultural and religious identities, but it’s important to accept the fact that it’s hard to succeed economically due to poor productivity, Government regulations, custom restrictions, and limited education of the Indian population.

IFC will do its best to understand the Indian society and collaborate to bring innovative products to market.

Q: Please, tell us about what IFC has done so far in India.

A: IFC has participated in various exhibitions to explore Indian FFC markets. In 2019,. It collaborated with KOTRA Chennai to identify specific FFC technology to supply the needs of home appliance manufacturers and automobile companies in India.

The meeting with local partners we informed them of 26 years of cable equipment manufacturing capacity, and emphasized that it is advantageous to produce and supply directly in India for long-term cable demand expansion a stable supply of cables and an active response to new product development is critical. We have had direct requests of interested companies in conjunction with the Indian government's domestic manufacturing policy. IFC will continue to visit the manufacturers who supply the cables and explain the advantages of producing and supplying them directly with IFC equipment that is recognized worldwide. The goal is to improve the reliability of continuous cable purchases from home appliances and automobile manufacturers.

Companies that want to replace the imported cable with local production, share their cable specifications, raw material information and make samples that support them. IFC will actively cooperate with their new cable business. Getting more machine installed and personnel trained are the key goals. The company has supplied cable production machines, consumables, raw materials, and post-processing machines to One-Stop, so that the company can focus on producing cables. The company plans to conduct marketing aggressively to enter the Indian market by combining information collected through various methods such as the New Delhi auto parts exhibition and market information discovered through the government's export support policy.

Q: What was your impression of Indian economy and culture?

A: India is very embracing for Korean companies that have entered the country, with a wide gap between the rich and the poor, a system of identity deep in society, and different languages spoken in different regions. In particular, the economic structure developed by some large corporations seems to show the a disproportionate aspect of Indian society due to severe wealth concentration. However, with their culture, which has been protected for generations, is the pride of Indians, and India's infinite potential to dream of a new leap with economic revival is difficult to estimate. India's efforts to open its doors to the world today, the growing enthusiasm for education, the young brains of India from all over the world, will make India great. There is no question that these Indian entrepreneurs will come to lead companies worldwide most likely a CEO of a global company, potential is endless.

Q: I would like to hear about your biography and your point of view in regards to international cooperation.

A: I was born in 1959 and graduated from Seoul National University of Science and Technology in 1981. I got my first job at Hansun and produced Flat Cable for the military for the first time in Korea after obtaining a certificate from an American FFC Corpotation.

Since then, he has been working with Sangmoowon and Seotong to develop overseas sales and overseas certification technology development. In 1994, he founded International Fleet Cable and succeeded in localizing cable machines. The company has been recognized for its technological powers by exporting to the world such as Ricci Sony, Foxconn, Nicomatic, and Parlex, and won the $ 1 million Export Tower Award in 2002 and the $3 Million Export Tower Award in 2010. In order to improve the overall company's management capability, he has completed the KAIST, Seoul National University GLP, and Korea University AMP top management courses. Today, the Korean economy is under the influence of the world economy. In particular, our economy, which has poor resources and consumption markets, is especially vulnerable to external stimuli. It is necessary to find ways to cooperate with other companies with the same interests, to cooperate with each other, and to coexist with each other.

Q: Please let me know if there is anything else you can introduce about IFC.

A: IFC was founded in 1994. IFC succeeded in localizing card cable machines, which all said was impossible. In recognition of its technological prowess in the card cable market, which was dominated by Japan, the company even exported machines to Japan. IFC has grown into a leading player in the FFC industry today by investing heavily in technology-intensive businesses. The company currently has five employees, most of whom have been in service for more than 10 years. We are employing only the personnel necessary for technical development and machine assembly and handling the remaining outsourcing services. In particular, while continuously communicating with buyers in the US and Germany, we are continuing to actively respond to requests for equipment upgrades, new product development, and post-processing machine development to improve their productivity.