Says Chairman Kang of Ediston Motors in Seoul

By Feature Editor Ms. Cho Kyung-hee, Reporter Jung Won-shik

“We are going to be a company beyond Tesla Motors in 10 years,” said Chairman Youngkwon Kang of Edison Motors in Seoul at a recent interview with The Korea Post media, publisher of 3 English and 2 Korean-language media since 1985. Then he said, “One of our strategies is focusing on the performance and design of the car that the consumers want.”

“So far, manufacturers have produced cars with their own mindset and design to reduce costs, but now it's hard to take the lead in the market in a traditional way.” Excerpts from the interview with Chairman Kang follow:

Q: Please tell us in detail about Edison Motors's electric vehicles that are differentiating themselves from other industries.

A: 20 years of technology, carbon fiber body, motor, electronic control technology, battery pack design, etc.

We have the ability to design and manufacture motor, electronic control technology, and battery packs, which are the three core technologies of electric vehicles. Based on this, we do our best to ensure that Edison Motors products have three beats: technical, quality, and price competitiveness.

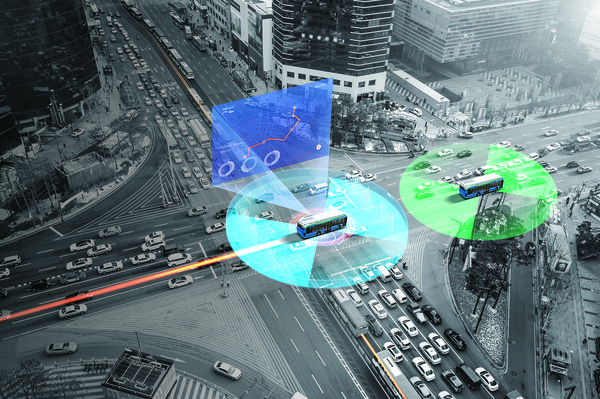

"Edison Motors has the world's best electric bus technology. Since 2010, commercial electric buses have been developed and produced on their own and are rapidly developing in both technology and quality. We also have our own production capacity for motors, electronic control technologies, battery packs, and so on, so we have a production system that will reduce costs even more as we can mass-produce them."

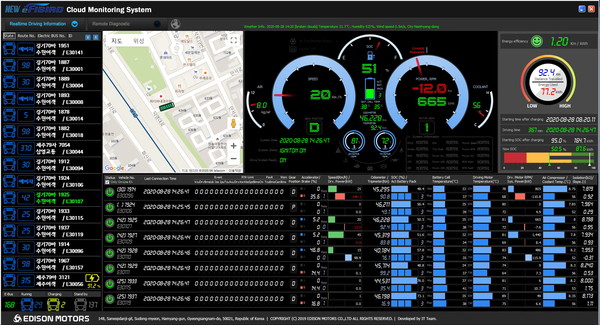

In addition, BMS, which manages battery packs for Edison Motors electric buses, is the third-generation Smart BMS (typically the second-generation BMS is widely used), and the third-generation Smart BMS uses active monitoring of battery cells and modules to explore faulty cells, assess battery conditions with precision, and dramatically improve battery performance and longevity by maintaining a balance between battery cells and modules through smart management. In particular, Edison Motors' Smart BMS is built on a cloud platform, enabling real-time management and control of battery performance and motor electronic control of electric buses through mobile devices such as smartphones. This smart BMS management allows '9 years or 900,000 km warranty for battery packs and motors'. The strength of our company's proud smart BMS lies in precise poor cell management. The second-generation BMS adopted by a third-generation company may have seen overcharging or over-discharging due to poor cells, resulting in cell well-being and fire accidents reported in the news, and our company manages to prevent cell-swelling or fire from occurring through smart BMS, and third-generation Smart BMS is the best technology in the world.

Currently, we are developing the MSO Coil Motor with a maximum output of 130kW and 160kW, and we are conducting a dynamo test with the aim of mass production in 2021. The latest MSO Coil Motor, which combines Edison Motors' technology, will be installed in electric buses, electric trucks, electric yachts, and electric ships, and will be applied to electric passenger cars, electric SUVs, and electric supercars in the future. In the future, MSO Coil will be made from light aluminum materials and applied to various means of transport such as Electrical Air Vehicle (PPAV), Drone, and Electric Airplane. It is expected that it will maximize the import substitution effect through localization of material parts equipment and export battery packs equipped with MSO Coil Motor and Smart BMS.

Q: If you have any knowledge of technological competitiveness that surpasses Hyundai Motors, please introduce it?

A: One of the things I always say is that We’re going to be a company beyond Tesla Motors in 10 years. One of our strategies is focusing on the performance and design of the car that the consumers want. So far, manufacturers have produced cars with their own mindset and design to reduce costs. But now it's hard to take the lead in the market in a traditional way. We live in an era where it's important to find favor with consumers with more innovative and superior products. There will be a time when cars with technological competitiveness and superior design and performance that the consumers want will be noticed. We need to prepare for this.

In the current electric bus production technology, we are confident that our company is the best in the world beyond Korea. High-quality electric buses can be produced at reasonable prices by securing and producing technologies related to driving systems such as vehicle chassis platforms, electronic control systems and better batteries.

But we don't stop here, and we always think about what we're missing and what we want to reinforce. I'm sure consumers will choose the competitive Edison Motors electric buses because we are making the parts that they desperately need—the ones that have the best power, the reduced failure rate, and the AS."

As we have always been successful in commercializing electric buses in Korea with customer-centered thinking and groundbreaking ideas, we are confident that we will continue to become one of the world's leading eco-friendly electric vehicle manufacturers with innovative technology that no one has ever thought of."

Q: Tell us the story of India's entry into the country and its entry into the local factory, where export barriers are high. And please let us know if you have any good ideas about the Indian government or related industries to promote bilateral economic cooperation.

A: India has a per capita income of around $2,000. The agricultural population still accounts for half of the population. Since the opening of India's economy in 1991, global companies have continued to enter India and engage in business activities. Korean conglomerates have also been expanding their business in India for more than 20 years since the mid-90s. Most large manufacturing companies such as Hyundai Motor, Samsung, LG, and POSCO have succeeded. Starting with labor union activities that began to rise in the late 1980s, labor productivity has weakened every year compared to advanced countries due to a steady increase in labor costs. In order to enter large markets such as China and India, we have pursued local production strategies and secured competitiveness by expanding overseas investment. It would be best to produce and export in Korea, but we have been steadily pushing for market-entry and market expansion through local production in terms of price competitiveness. Korea is a manufacturing powerhouse, but it is now moving to China, Southeast Asia, India, etc.

Compared to China and Vietnam, India is not yet a mature market. If China's per capita income is around $8,000, India is far below that level.

The Indian government's basic policy is focused on industrialization that increases agricultural productivity and aims to increase gross national product so that the entire nation can prosper. The population is over 1.3 billion, which is equivalent to China, and if per capita income is still around $2,000, it will be classified as a developing country.

However, India continues to grow steadily, with an annual economic growth rate of more than 7 percent, based on democracy. Although it has been slowing down due to the recent two to three years of currency reform and tax reform, investment, and education in social infrastructure, new growth engine IT and bio sectors have world-class competitiveness.

Starting from June 2019, the second phase of the Modi administration will show many developments and changes over the next five years. The Corona crisis is now shared by the world, but with the enormous domestic market, industrialization and urbanization will accelerate, and manufacturing and service industries will expand.

The Indian government is advocating the 'Worldwide Manufacturing Hub' with its 'Make in India' policy. In other words, the potential of the Indian market is endless, so you should build your own factories, sell them, and export them to India's large domestic market.

In pursuit of such a policy, the direct import barriers of finished and intermediate products are naturally high, and they adhere to the high tariff policy. For example, imports of finished cars in Korea are less than 8%, but India has to pay a 100% tariff. In other words, a car that can be purchased for 20 million won in Korea is 40 million won in India, and 45 million won including registration fee.

Most global companies are looking at the future Indian market and trying to secure manufacturing facilities in India. India's Modi government expects the policy to continue in the future.

Then, the direction of Korean companies' advance into India is set. Small and medium-sized enterprises and other companies preparing to enter the Indian market are at risk when securing manufacturing facilities and investing in plant facilities in India. To reduce this risk, joining hands with Indian partners to share roles will make it easier to advance, but the key is selecting partners and operating strategies for partnerships with Indian partners. Korean companies that are not familiar with this area insist on entering the Indian market, except for large companies.

India, with its long-standing democratic policies, is less amenable with regards to the government's land expropriation policies needed for development. Because it is not easy for individual foreign companies to secure factory sites, they have been solving difficulties in entering the complex system by creating a government-level industrial complex. In particular, Japan's exclusive industrial complex has been built under the leadership of the state in major industrial cities.

In order to make it easier for Korean companies to enter India, we should focus more on supporting such work through a memorandum of understanding between the two countries.

Q: Please introduce yourself in detail.

A: In 1985, I was originally a producer (PD) and produced "Unanswered Questions" and a number of other programs when I was a PD. My program once had the highest ratings ever, over 40 percent. And I thought it would be too unfair if I didn't do business, so I quit my job and started my own business. At first, I wanted to work as a cell phone battery manufacturer, but I couldn't get the funds because it was during the IMF period, so I had to start a company that produced broadcasting programs first, and SBS gave me a lot of consideration. MBC's "TV Unique Amazing World," which was aired with high praise, was made when it was an outsourced production business. Although it was successful with 1.2 billion won in sales in the first year, 4.5 billion won in the following year, and 10 billion won in the following year, I passed on the successful outsourcing company to my juniors and invested in ES petition, a renewable energy company in 2003 to enter the eco-friendly business. The company has achieved great success, continuing its annual sales growth of over 25 percent, and has challenged itself as a representative of the electric car company. The electric car company that was acquired started with the OooHuaIva eco-friendly electric bus business and developed eco-friendly buses since 1998. It was the first electric bus to be certified by the Ministry of Land, Infrastructure, and Transport in 2010. It was sold to Chinese Taichi Motors in 2015 and I took it over in 2017. With the acquisition of the electric car company again, the company changed its name to Edison Motors with the will to "pass Tesla" and is working hard to develop innovative electric vehicles.

Edison Motors' strengths

First: experts and talents in each field united

CTO Young-Soo Han in charge of the Chief Technology Officer in the Business Strategy Division and Woo-Yong Jung (29 years experience), head of the Research Institute, SMART Electric Vehicles, Electric Buses, Electric Trucks, Vans, Electric Sports Cars, Electric Cleaners, Electric Tractors with International Competitiveness Etc. are being developed.

He is in charge of purchasing by recruiting CEO Jeong-ik Lee (28 years experience, CEO of the management planning division), who has worked at GM Korea for 25 years as a purchasing manager.

Jung-min Park, co-representative of Edison Tech, who has worked as the head of the BMS development team at the development center of LG Chem's Battery Business Division, develops SMART BMS and produces battery packs.

COO Jeong-ik Lee (28 years experience, Chief Operator Officer) is managing all divisions, who has worked at GM Korea for 25 years as a purchasing manager. CTO Sung-Min Hong(33 years, head of the Research Institute, DeaWoo Motors GM Motors etc. ) is leading the development of SMART Electric Vehicles, Electric Buses, Electric Trucks, Vans, Electric Yachts, Personnal Air Vehicles, Electric Drones...

Jung-min Park, co-representative of Edison Tech, who has worked as the head of the BMS development team at the development center of LG Chem's Battery Business Division, develops SMART BMS and produces battery packs & VCU for Autonomous.

In addition, Veteran Engineer Young-Soo Han in charge of the Chief Technology Officer in the Business Strategy Division who has worked for Kia Motors for 33 years, are in charge of the entire production process.

CFO Bong-Cheol Cha (23 years experience, CFO of the financial planning division) was scoutted July 2020, who has worked at ESG(the company of New Energy Division) for 25 years as a chief financial officer.

In addition, Veteran Engineer Kim Doo-seop, who has worked for Korea Fiber for 28 years, and Han Young-soo, who has worked for Kia Motors for 33 years, are in charge of the entire production process.

Second: Edison Motor's unique lightweight technology

By producing a body such as an electric bus made of composite material (CFPR) and reducing the weight of 1.5 to 2 tons compared to the same class, it achieved 20 to 30% power consumption efficiency based on no-load constant speed driving, heater and air conditioner off. This material has excellent anti-corrosion properties and is resistant to fire. In addition, the strength to specific gravity reaches 9.6 times that of steel and 4.9 times that of aluminum, and the rigidity to specific gravity is 1.7 times that of steel and 1.8 times that of aluminum.

Third: In-house development of the three major technologies of electric vehicles: motor, electronic control, and battery

The MOS coil motor jointly developed by Edison Motors with the Institute of Production Technology is a motor capable of producing more than twice the torque of its class.

The 130Kw MOS coil motor jointly developed with the Korea Institute of Industrial Technology can produce power over 6000cc of an internal combustion engine (M275 engine, which is a Mercedes S class 12 cylinder, 5513cc power output 3500rpm torque 830 N-m).

MSO (Maximum Slot Occupation) coil is an electric vehicle motor technology that can increase the rate of conductor winding inside the motor slot up to 90%. A total of 38 domestic and international patents have been obtained a patent on an invention.

This technology was introduced as ‘Korea-developed next-generation electric vehicle motor technology’ at the world's largest motor exhibition held in Germany in June 2018, and is a technology that is drawing attention from around the world, such as being nominated for 3rd place at an official event.

Fourth: Development of next-generation hydrogen fuel cell bus and hydrogen fuel cell truck

In June 2017, Edison Motors entered into a strategic partnership with a leading technology research institute for the development of hydrogen fuel cell bus, and through joint research, it is a next-generation vehicle that has superior performance, higher energy density, and superior power, lifespan, and stability compared to existing vehicles. It showcased hydrogen-fueled battery buses and hydrogen-fueled battery trucks and exhibited hydrogen-fueled battery buses at a motor show held in China in October 2017.

Since the operating principle of the fuel cell does not include a combustion reaction, it does not emit pollutants such as CO, HC, NOx, etc., and thus a driving part that reciprocates like an engine's piston is not required, so energy conversion efficiency is very high.

CEO Young-kwon Kang Experience

2017.09~Present CEO of EDISON TECH Co., Ltd. (Smart BMS and battery pack developer Park Jung-min Joint Representative Director)

2017.01.~Present EDISON MOTORS (electric vehicle production), i EDISON (automobile import/export sales and sharing business),

Siberian Resource Development (Acquired permission for bottled water of Lake Baikal), SOLAR ENERGY (ESS&CPV solar power), ESR (Gyuseok mine 3 million pyeong)

1998.01.~Present Representative Director of ENERGY SOULUTIONS Co., Ltd. (formerly CAA: Creative Artist Association) And major shareholders

2005.07~2018 ES CHEONGWON Co., Ltd. (Sold to a partner in 17-18: US$100 million)

2003.10~2014 EST Co., Ltd. (Sold to a partner in 2014: US$40 million)

1991.05~1998.01 SBS Liberal Arts Bureau PD'It Wants to Know' Directing, Pyeon Seong-guk, Uiju Team Leader, Planning Team Leader

1985.04~1991.05 KBS Planning Production Room PD (11th public recruitment)'Entertainment Broadcasting', etc.

Graduated from the Department of Sociology at Yonsei

University in 1985 Graduated from the Graduate School of Media and Public Relations at Yonsei University in 1994 (Master)

2018'Korea Economic Leader Awards', 2018 Korea Top Leaders Awards', '2018 Korea Kniguk Industry Awards', '2018 Korea Innovation Awards Electric Vehicle Industry Grand Prize'. ‘2017 Innovative Koreans & Power Korea Grand Prize’, 1996 inaugural special four-part “Koreans and Japanese” SBS Excellent Works Awards (27% viewership rating), etc.