Pioneer in the textile, garment industry in Korea

By Special Feature Editor Kim Hyung-dae

Last year, Seoul National University celebrated its 74th anniversary, and in celebration of its founding, Chairman Kihak Sung of Youngone Corporation was honored as the ‘Distinguished Seoul National University Member.’

Chairman Sung founded the Youngone Corporation in 1974 and is considered Korea’s pioneer in the production and export of products in OEM, especially in the garment industry. Having been appointed as the Chairman of Korea Federation of Textile Industries (KOFOTI, 2014-2020) and Chairman of International Textile Manufacturing Federation (ITMF, 2018-2020), he is considered to be a great contributor to the promotion and development of the textile industry.

The life of Chairman Sung is a sheer example of a success story for a businessman in Korea. Here are some examples of media accounts concerning Chairman Sung:

Inspired by his love of nature and outdoor pursuits, Sung founded Youngone Corporation. His commitment to the environment, and an unrelenting standard of quality, have provided the long-term vision and standards for the company’s philosophies.

As a result, Youngone continues to be known as a pioneer in the outdoor industry and continues to improve its product and encourages employee development for a better outcome of all aspects.

Youngone began manufacturing sportswear and down jackets in Seongnam, South Korea and has since grown to become the premier manufacturer of outdoor apparel, footwear and gear.

Today, Youngone owns and operates production facilities in various parts of the world including Bangladesh, Vietnam and El Salvador. Youngone employs more than 70,000 people directly, and more importantly, the company supports the families and communities that have contributed to the growth of the company for over 40 years.

This integrated support system has enabled Youngone to play an important role in the socio-economic development of the countries they work in. Their broad product and service portfolio keeps growing, thanks to the investment in the people, Youngone was able to contribute to diversified group.

To further enhance the company’s capabilities and to encourage and support vertical manufacturing, the materials division of the company was launched. The company produces both woven and knit fabrics as well as a variety of insulations that are vertically integrated into the manufacturing process.

This allows the company to meet the ever-changing needs of the customers by shortening lead times and improving quality control.

It also helps decrease the carbon footprint required in long haul transportation of materials around the world, which is an important value to the company and to its customers.

As a result of its close collaboration with customers the company’s apparel business has grown organically since 1974.

Overview of one of the Youngone factories located in the Korean Export Processing Zone in Bangladesh:

As an outgrowth of its quality and dependability, customers began asking Youngone to continuously expand into new categories. While the company’s heritage is in down outerwear, Youngone has expanded its technical expertise to cover the needs of the outdoor market.

This includes woven sportswear that incorporates stretch, easy care and versatility as well as rainwear, synthetic insulated outerwear and casual streetwear. Additionally, the company offers performance knits and activewear that combines functionality with comfort. Youngone introduced seam-sealed garments to Korea in 1982, setting a new standard for waterproof materials. Youngone is very proud of its reputation as a continuous pioneer in the field of outdoor apparel.

To provide the customers the best possible fabrics for their garments and gear, Youngone created its materials division in 1993 to facilitate and manufacture world class components. Beginning in the 1970’s with synthetic padding for White Stag, its portfolio has grown to include woven nylon and polyester fabrics along with polyester fleece and knits. Youngone produces single jersey, double interlock and rib fabrics with its circular knitting machines. Youngone offers a variety of insulations including Excelloft® and most recently VX®, its breathable synthetic performance insulation, water resistant, quick drying, stretchable and hypoallergenic.

As part of its expanding platform, Youngone established Designer Textiles Vietnam. These vertical design and manufacturing capabilities enable its customers the swiftest design and development cycle as well as access to state-of-the art digital printing capabilities.

Youngone produced its first backpack in 1998. Since then Youngone has expanded to include technical packs, luggage, canvas totes and, most recently, luxury handbags. Youngone also offers internal steel frame construction for lifestyle bags, which is an important outgrowth of the active outdoor lifestyle and growing business opportunity for the customers.

Footwear became a significant part of the company’s business in 1996. Youngone’s operation includes the production of safety footwear, winter boots, and outdoor and casual footwear styles. The duty-free access to the factory in Chittagong, Bangladesh has facilitated the world’s best brands to partner and strategize on this state-of-the-art facility. The company looks forward to eventually employ 30,000 associates and offer an even wider variety of styles and development opportunities to its customers.

Corporate Social Responsibility: Youngone is committed to evolving its CSR practices through meaningful programs that makes a difference in the world. Its legacy will be created through deliberate and consistent actions, which results in long lasting benefits to its workers and the planet.

In conjunction with its land reclamation efforts in Bangladesh, Youngone supports the following organizations:

In 2012 Youngone created STEY, encouraging its employees to engage in a variety of activities to support the earth’s well-being. These include cleaning local neighborhoods, tree planting and recycling drives.

Through our association with various NGOs such as Warm Clothes for Children, World Vision, Red Cross and Good Neighbors, Youngone has donated over 5 million clothes to people in need around the world and also supported communities affected by the earthquake in Nepal with tents, worth up to $100K.

CCCP, launched in 2002, is a project in Bangladesh providing financial support for small businesses. It started with 1,000 members and since has blossomed to more than 18,000 members and now it provides education on reproductive, maternal and child health. As CCCP has grown, Youngone has contributed ongoing technical and advisory support to the organization.

Human Resource Development:

Youngone believes its employees are one of the greatest assets and encourages personal and professional growth. Understanding that both mental as well as physical health is critical for its employee’s well-being, the company began providing free medical treatment to the employees in 1986 and added counseling services in 1993. Each Youngone facility offers extensive training programs to foster its management and team leaders. Youngone is very proud to have many of its associates from the time it began, as well as a high number who exceed more than a decade of service.

In support of future generations, in 2008, Youngone began collaborating with three universities in Seoul, South Korea--Sookmyung Women’s University, Ewha Women’s University and Seoul National University-- to train students in hands-on apparel design and manufacturing methodologies. This attention to next generation development is an integral part of Youngone’s people development policy.

Additionally, Youngone carried out restoration project to preserve cultural heritage in Bangladesh. The residential complex, Baro Sardar Bari was built in 1892 with an addition in 1902. In its time, it was one of the most beautiful examples of colonial architecture, but the upkeep of the building had diminished over time and the building had fallen to ruins. The original furniture was commissioned to local craftsmen and has been installed.

For over 40 years, Youngone has incorporated specific strategies to decrease its manufacturing's impact on the environment with the intent of diminishing the ecological footprint. One of its ongoing projects has been rehabilitating 2,492 acres of land purchased in 1999 in Bangladesh, now known as the Korean Export Processing Zone (KEPZ).

Under the Blue & Green initiative, 2.4 million trees have been planted in KEPZ of which 300,000 have been planted in the last two years, created 25 lakes and water bodies that conserve upwards of 500 million gallons of water and control floods and sediment flow in neighboring settlements. This initiative has helped enrich the Flora & Fauna of KEPZ, making it an environmentally sustained, eco-friendly industrial zone.

In a recent survey done by the Department of Botany, Chattogram University in Bangladesh, 412 species of Plants have been found inside the industrial zone. This incident is a remarkable achievement towards Chairman Sung’s vision of creating an eco-friendly industrial zone.

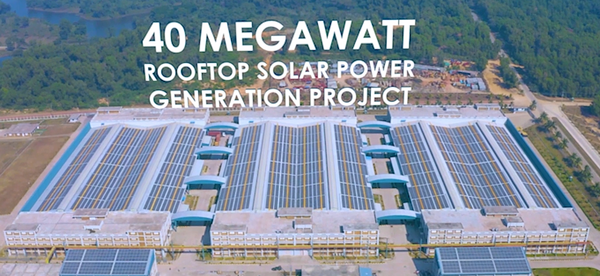

Chairman Sung has also initiated the commission of a massive 40-megawatt rooftop solar power generation project. 5-megawatt capacity has already been installed, with the remaining 35 megawatts expected to be completed soon.

Once complete, the state-of-the-art solar panel installations will cover the roofs of every single industrial building throughout the zone. It is believed that the completed project will be the single largest rooftop solar power project in Bangladesh. This project will not only harness the power of the sun to meet its increasing energy needs in a sustainable manner, it will also provide any surplus renewable energy to the national grid, demonstrating its commitment to social responsibilities.

To support the development of an integrated vertical supply chain of the industry, Chairman Sung has boasted to house the largest Man Made Fiber (MMF) textile facility in Bangladesh. Karnaphuli Polyester Products Ltd. (also known as KPP), has added two new facilities, spanning over 40,000 square meters. Addition of two more facilities are to be built in the upcoming years.

To contribute to Bangladesh’s economic development, Chairman Sung has extended and signed the tripartite agreement between KEPZ, Bangladesh High-Tech Park Authority (BHTPA), and Startup Bangladesh under the Ministry of ICT. Chairman Sung aims to establish a high-tech industrial park within its premises.

KEPZ will focus on developing infrastructures in its dedicated 100 acres of land to attract foreign investment in IT and technology-based industries which may strengthen the start-up ecosystem as well. This agreement will also support entrepreneurs through upskilling by way of startup camps, design thinking and innovation projects.

Bangladesh High Tech Park Authority will create digital entrepreneurs by developing an innovation ecosystem in the country to increase investment from the private sector.